We were tasked with designing and building a cleaning system to clean 20,000 litre emulsion paints by a UK paint manufacturer. The System had to enter the vessels from the top and retract back out of the vessel for the production to start up again.

We came up with a system that would unload and retract using pneumatic air reelers and a Karcher high pressure cleaning unit. The reelers would insert a high pressure spinner head that would clean the vessels and rinse them before adding a biocide to treatment to get rid of any bacteria that can cause emulsion to go off.

These units will be fitted to 22 vessels at the UK plant and will be rolled out across the global manufacturing plants to standardise across the groups cleaning processes.

With the ever increasing push to go green we designed and built a fully electric hot water high pressure cleaning system for a Steel manufacturer who wanted to move away from the diesel units they had on site.

The units are capable of delivering hot water at 75 degC at 20litre per minute. With an output pressure of 140 bar and a twin pump system this is an ideal system for cleaning even the dirtiest forging plants. They liked it so much they bought a second unit.

The system is fitted with a touchscreen control and can be remotely monitored to check pressure, flows and temps and also make the maintenance aware of any issues that may arise.

Our engineers completed the install of the HP unit and a ring-main with high pressure stainless steel pipework and multiple hose-reels fitted with dual use guns that can be automatically changed from low pressure for foaming to high pressure cleaning at the turn of a lever fitted to the gun.

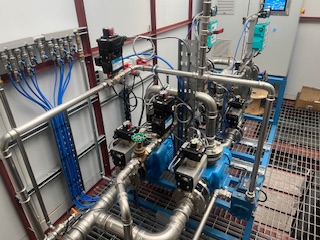

A plant room built for a cleaning project by us. The system uses steam to create high temperature water via heat exchanger. The steam is also used to create warm air for the drying process of the clean.

A Karcher high pressure hot water system is used to give 30-50 lpm at 140 bar 75 deg C. The control cabinet and software was developed by us as a bespoke system for this particular process.

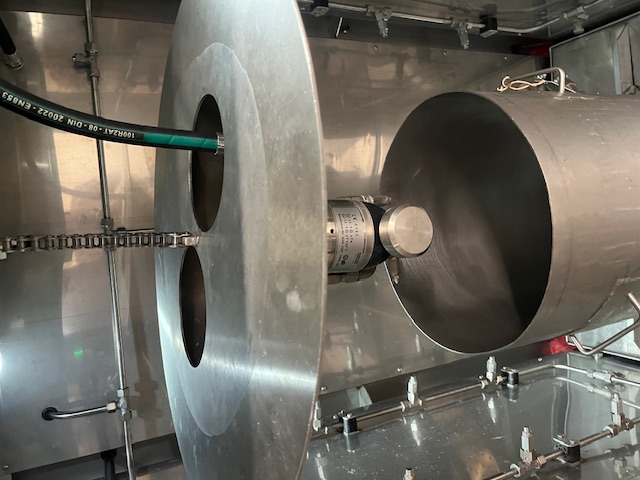

Three sizes of cleaning cabinet are used to clean different sizes of ingredients vessels. The process cleans the externals and the internals then drys the vessels to make sure that no moisture is present to cause contamination in the powders that are used in the vessels.

The high pressure spinner heads clean the internals and the spray bars around the cabinet do the externals. The spinner head manifold has a warm air duct fitted to dry the vessels.

Another project for the same customer we were asked to build an automatic IBC cleaner using high pressure cold water.

Our fabrication department designed built this platform and insulated enclosure for a River Water recovery pump System.

Pump skids for the self-priming pumps and filtration systems

Staircase, handrails and doors for the skeleton of the building were built and fitted by our team of engineers.

Cat 5 water tanks for the booster pump to supply the water on 250 mtrs of 4″ stainless steel pipework also fitted by our engineers

Fully automated sytem with air actuation and complete control system that is remotely monitored by our service engineers and software team.

All electrical installation carried out by our engineers

The finished platform and cladded building enclosure completed this project by our engineers.

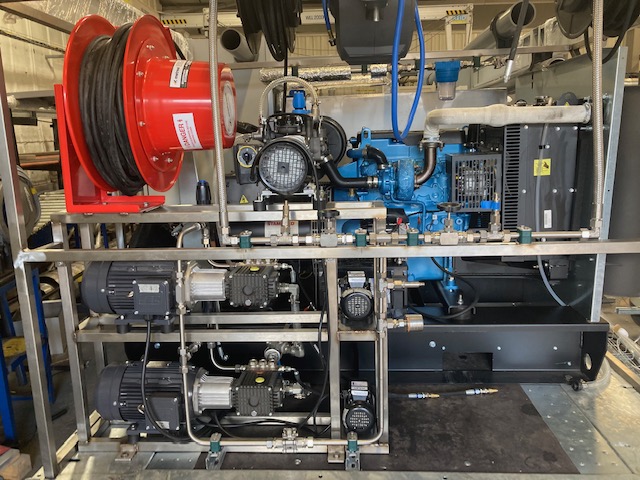

This was the pump stack on a trailer mounted High Pressure Water and detergent cleaning system for Rolls Royce. Designed for use in the hangar or on the runway using its own generator. Twin booster high pressure hot water pumps. Detergent dosing and vacuum pumps all running on a software system designed by our engineers to be remotely accessed to monitor the performance of the units.

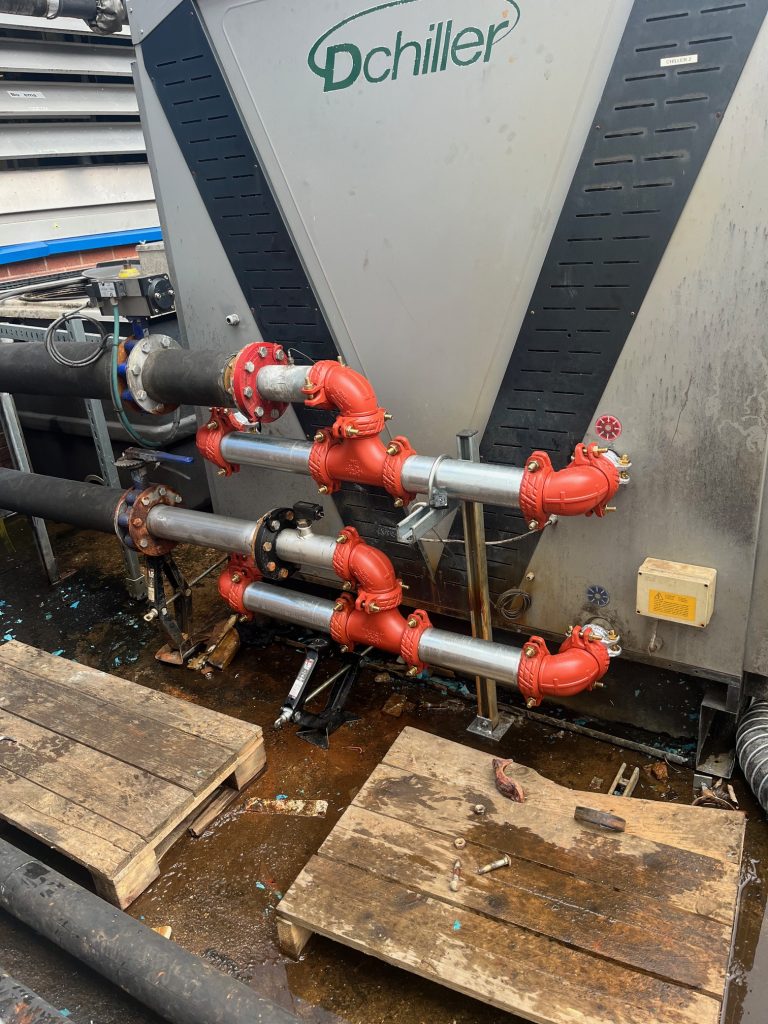

We had a call from a customer with leak which was caused by corrosion of the existing pipework and damage from unwanted visitors to the site. After jacking up the pipes and fitting temporary drainage we were called into replace the pipework. Victaulic grooved pipework replaced flow switches welded in position and regalvanised within the given timeframe. The Chiller units were back up and runnning and so was their production.